Innovation, Flexibility, Performance

Sonatest is proud to extend its WheelProbe family with the introduction of the WP2:128. With a larger footprint, it builds on the success of its big sister, the WP2:64, and further enhances your mapping capabilities. The width of the inspected zone is increased from 50 to 100 mm. With a reinforced aluminum and carbon structure, the Wheelprobe2 is lighter and retains its proven robustness. Day after day, you can rely on its performance, even for the most delicate tasks. The Wheelprobe2 is equipped with 3 LEDs that display alarms set on the device in real time. Add to this the remote display of the screen via the telephone holder on the handle, and the operator can concentrate on obtaining consistent, high-quality ultrasound data, and diagnose immediately, with total confidence.

Thanks to the choice of handle configuration in vertical or transverse position, with adjustable angle for operator comfort, and the remote control positionable for right- or left-handed operators, the Wheelprobe2 offers ideal ergonomics. The different shapes of support rollers - flat, diabolo and precision - will enable you to configure your Wheelprobe2 in just a few moments for inspection of a flat composite surface, or for corrosion mapping on a pipe, in longitudinal or axial mode. You can also scan edge-to-edge parts, concave, convex or irregular surfaces. The Wheelprobe2 can be fitted with laser guidance to keep your scans on the right axis. The laser pointer gives a high degree of confidence when recording multiple scans or when moving over a large area. Wheelprobe2 connects to most multi-element electronics. It is available with interchangeable cables of different lengths, fitted with different connectors.

In brief

- Laser guidance

- Wireless control box

- 3 function buttons

- 3 status LEDs

- Ergonomically designed

- and adjustable

- Flat and curved surface

- Detachable cable

- Lightweight, reinforced chassis

- Resolution down to 1.5 mm

- below surface

- Safety hook

- Different roller configurations

Composites inspection

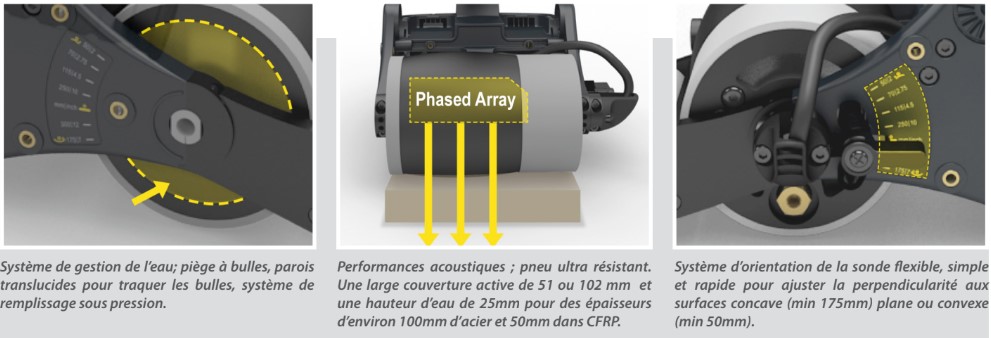

The WP2 provides the best solution for mapping large composite surfaces. With its excellent sub-surface resolution, close to the millimeter, the WP is the best alternative to immersion control. Available in frequencies of 10MHz, 5MHz, 3.5MHz and 2MHz, the WP2 has a near-water acoustic impedance

and,

like its predecessor, generates an ultrasound signal of exceptional quality. Different handle configurations, adjustable laser guidance, remote LED alarm display, remote control with start/stop, reset and index change functions, and an offset display, on the handle, make this package unique, superior and still unrivalled!!!!

Recommended kit for composite

- Wireless remote control for efficient operation

- Flat front roller for part edge scanning

- Adjustable laser pointer for accurate scanning of large parts

- Remote display holder for monitoring inspection results directly on the WP2

- Display mounting for better visibility during scanning

Precise alignment with laser pointer

Edge-to-edge scanning with front roller

Corrosion monitoring

Performing complete, reliable inspections and generating corrosion maps has become more than a trend; it's a necessity. Thanks to the efficiency, performance and accuracy provided by WP2, it is now possible to monitor large areas and rapidly analyze data to determine whether critical or urgent action is required. What's more, this technique enables the user to compare large quantities of data over time to carry out preventive maintenance, reducing potential downtime. With WP2, the level of confidence is significantly increased as decisions are based on much more detailed data.

Whether for axial or longitudinal inspection, using the appropriate support rollers or a scanner, the flexibility of the WP2 is the tool of choice for fast, accurate corrosion monitoring.

Recommended kit for corrosion

- Wireless remote control for efficient WP2 operation

- Complete set of front and rear support rollers

- Diabolo-shaped rollers for longitudinal scans; for optimum coupling to pipes or other cylindrical shapes

- Precision rollers (small wheels); for easy adaptation to irregular surfaces (welding) and orientation of scanning direction.

- Flat rollers for scanning right up to the edge of parts

- Adjustable screen support for easy viewing during use

(Top image) Precision rollers

(Bottom image) Axial scanning

Choose your Wheelprobe 2

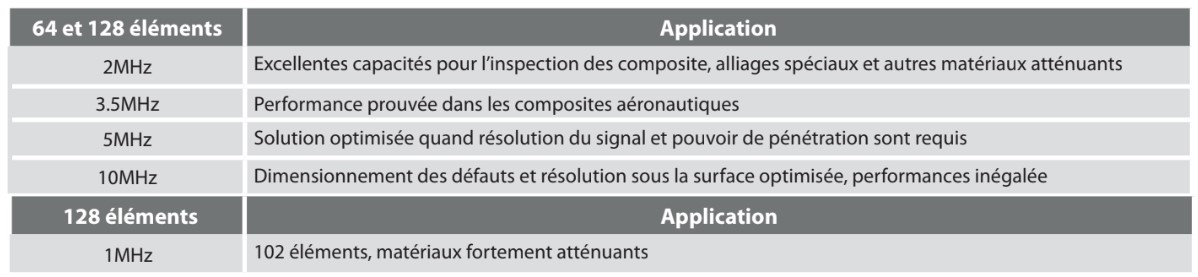

5 frequencies to choose from

WheelProbe selection: number of elements and frequency

Choice of handle

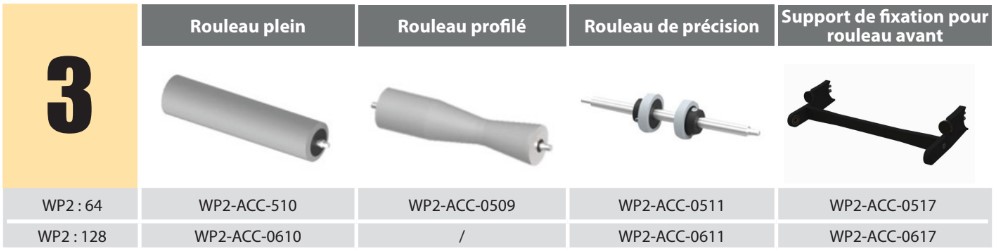

Choice of support roller

Cable selection

Other accessories

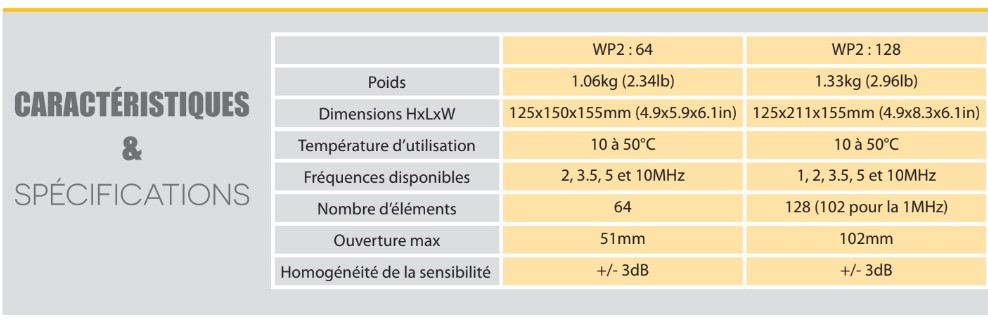

Features and specifications