You can contact us by email at infosof@sofranel.com or by phone at +33 (0)1 39 13 82 36.

| Screen | 7-inch color display, 800 x 480 pixels |

| Memory | 8 GB internal flash memory |

| Regional Setting | Metric and imperial units and support for multiple languages and time zones |

| Power supply input | 12 V +/-25 % / 1,5 A |

| Dimensions | 250 x 162 x 62 mm |

| Weight | Env. 1525 g (pile incluse) |

| Battery | Lithium polymère, 3,6 V, 14,0 Ah |

| Battery life | > 8h (in standard operating mode) |

| Humidity | < 95% RH, no condensation |

| Operating temperature | 0°C - 30°C (under load*, instrument on) 0°C - 40°C (under load*, instrument off) -10°C - 50°C (not under load) |

| IP Classification | IP 54 |

| Certification | CE |

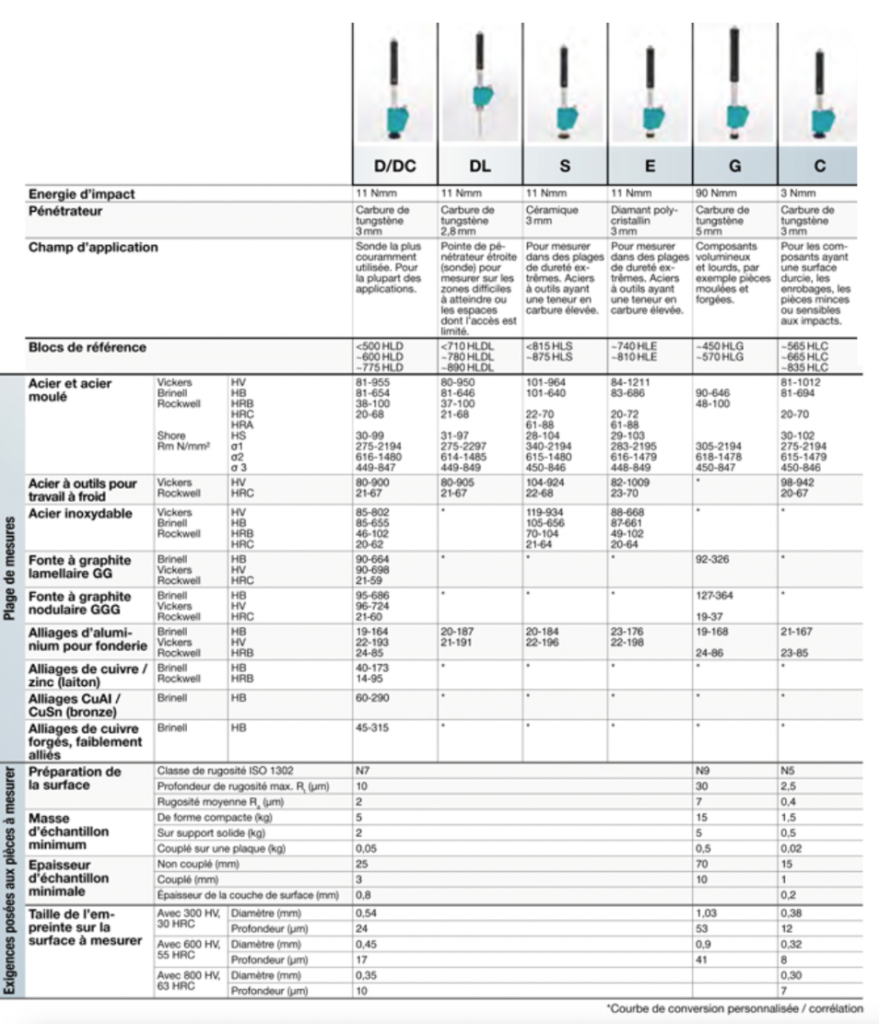

Wide measuring range: Leeb impact testers are ideal for on-site testing of heavy, bulky or pre-installed parts.

Wide range of hardness scales: Measurements are automatically converted to all common hardness scales (HV, HB, HRC, HRB, HRA, HS) as required.

Range of reference blocks: Extensive range of reference blocks for precise hardness measurement, available for each impactor with different hardness levels for regular verification.

Wide measuring range: Leeb impact testers are ideal for on-site testing of heavy, bulky or pre-installed parts.

Wide range of hardness scales: Measurements are automatically converted to all common hardness scales (HV, HB, HRC, HRB, HRA, HS) as required.

Range of reference blocks: Extensive range of reference blocks for precise hardness measurement, available for each impactor with different hardness levels for regular verification.

Equotip 550 portable Rockwell

High-quality static hardness measurement

Equotip 550 portable Rockwell

High-quality static hardness measurement

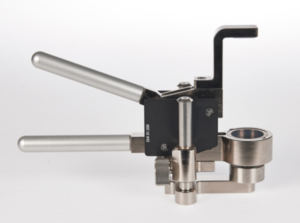

Especially suitable for thin parts: Particularly suitable for polished, scratch-sensitive parts or thin parts, profiles and piping with a thickness of less than 2 mm. Wide range of hardness scales: Measurements in HRC and HV with integrated conversions to HB, HRA, HRB and many other common scales in accordance with ASTM E 140 and ISO 18265. Suitable for a variety of geometries: Unique measuring clamp and support feet are available for the probe, enabling measurement on a variety of geometries as well as on very small parts.

Especially suitable for thin parts: Particularly suitable for polished, scratch-sensitive parts or thin parts, profiles and piping with a thickness of less than 2 mm. Wide range of hardness scales: Measurements in HRC and HV with integrated conversions to HB, HRA, HRB and many other common scales in accordance with ASTM E 140 and ISO 18265. Suitable for a variety of geometries: Unique measuring clamp and support feet are available for the probe, enabling measurement on a variety of geometries as well as on very small parts.

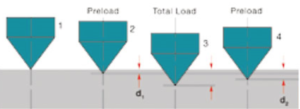

| Measurement range | 0-100 µm; 19-70 HRC; 35-1 000 HV |

| Resolution | 0,1 µm; 0,1 HRC; 1 HV |

| Measurement accuracy | ± 0.8 µm; ~ ±1.0 HRC over the entire range |

| Maximum hardness | 70 HRC; env. 1000 HV |

| Test loads | Preload 10 N / total load 50 N |

| Diamond indenter | Angle 100.0° ±0.5°, diameter of flat surfaces 60 μm ±0.5 μm |

Equotip 550 UCI

UCI measurement principle

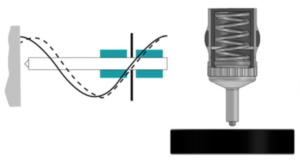

The UCI (Ultrasonic Contact Impedance) method uses the same pyramidal diamond as the conventional Vickers hardness tester. Unlike the Vickers test, no optical assessment of penetration is required, enabling rapid, portable measurements. The UCI method excites a rod to produce an ultrasonic oscillation. The test load is applied by a spring and typically represents a force of 1 to 5 kg (HV1 - HV5). As the diamond penetrates the material, the frequency of oscillation of the rod varies in response to the area of contact between the diamond and the material being measured. The instrument detects the frequency shift and converts it into a hardness value, which is immediately displayed on the screen.

Equotip 550 UCI

UCI measurement principle

The UCI (Ultrasonic Contact Impedance) method uses the same pyramidal diamond as the conventional Vickers hardness tester. Unlike the Vickers test, no optical assessment of penetration is required, enabling rapid, portable measurements. The UCI method excites a rod to produce an ultrasonic oscillation. The test load is applied by a spring and typically represents a force of 1 to 5 kg (HV1 - HV5). As the diamond penetrates the material, the frequency of oscillation of the rod varies in response to the area of contact between the diamond and the material being measured. The instrument detects the frequency shift and converts it into a hardness value, which is immediately displayed on the screen.

UCI equotip probe & accessories

UCI equotip probe & accessories

Special foot

The optional special foot increases measurement repeatability. It can be used for flat or curved surfaces.

For curved surfaces, there are two different openings, one for diameters from 5 to 25 mm and the other for larger diameters from 20 to 70 mm.

Special foot

The optional special foot increases measurement repeatability. It can be used for flat or curved surfaces.

For curved surfaces, there are two different openings, one for diameters from 5 to 25 mm and the other for larger diameters from 20 to 70 mm.

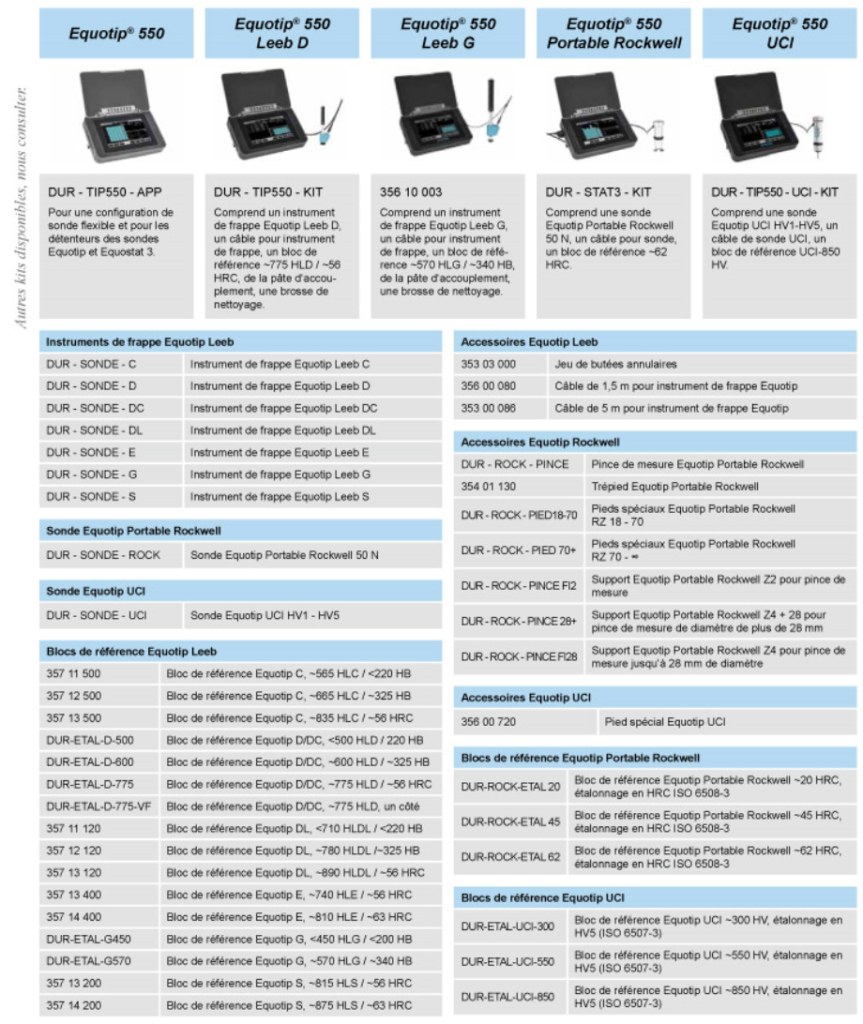

Pre-assembled kits

All kits include Equotip 550 platform with battery, power supply, USB cable, roughness comparator, CD with software, documentation, carrying strap and carrying case.

Pre-assembled kits

All kits include Equotip 550 platform with battery, power supply, USB cable, roughness comparator, CD with software, documentation, carrying strap and carrying case.

Do not hesitate to download the notice (PDF format) for this product: