You can contact us by email at infosof@sofranel.com or by phone at +33 (0)1 39 13 82 36.

| Description | |

|---|---|

| Profile Gauge with 0.8 mm diameter pins, 150 mm width |  |

| Profile Gauge with 1 mm diameter pins, 300 mm width | |

| HI-LO #1: Measures internal misalignment, gap, weld bead height, and pipe thickness (metric and imperial units) |  |

| HI-LO Simple #2: Measures internal alignment and gap (metric and imperial units) |  |

| CAMBRIDGE-TYPE or BRIDGECAM GAUGE #4: Measures weld beads, holes, and checks alignment |  |

| Weld Gauge H147: Measures preparation angle (0° to 60°), misalignment, fillet weld size, fillet weld length, groove depth, and crater depth |  |

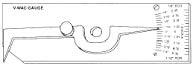

| V-WACTM Gauge #5: Easy and quick measurement of 4 essential parameters: depth, porosity comparison, porosity amount, and bead height (metric and imperial units) |  |

| AWS Gauge #6: Determines weld bead thickness, checks convex and concave tolerances of the bead (metric and imperial units) |  |

| Vernier Gauge: Measures bevel angles of 60°, 70°, 80°, 90° (metric units) |  |

Cratering Gauge E119: Designed to assess the condition of piping. Placed horizontally on the pipe surface, with the stylus positioned at the base of the corrosion crater. It indicates the depth of the crater by comparing it to the actual wall thickness of the pipe.

|

|

| Description | |

|---|---|

| Telescopic Inspection Mirror 131/1A: 350 mm to 1400 mm. Mirror diameter 60 mm. |  |

| Illuminated Inspection Mirror 131/2A: 152 mm flexible rod, powered by batteries in the handle. Mirror diameter 63 mm. |  |

| Description | |

|---|---|

Illuminated Magnifier 137

Sometimes detailed surface inspection is necessary to check the exact profile of the material or its cleanliness. Many environments may be poorly lit or dark, such as ballast tanks, oil, and gas reservoirs. The Illuminated Magnifier 137 is ideal for this task.

|

|

| The H131/1A safety torch/flasher is explosion-proof and complies with ATEX directives as Category 2 equipment. It is certified under the latest EN standards for electrical equipment in potentially explosive atmospheres. This allows it to be used in Group II applications, zones 1 and 2, gases IIA and IIB, with a temperature class of T4. |  |

| Description | |

|---|---|

Portable digital roughness meter managed by a microprocessor.

|

|

| Visiotactile comparator E125-1: Grit-blasted surfaces: 25, 60, 100, 150 µm |  |

| Visiotactile comparator E125-2: Shot-blasted surfaces: 25, 40, 70, 100 µm | |

| Visiotactile comparator Rubert and Rugotest E129-1: Grit-blasted surfaces: 0.4, 0.8, 1.6, 3.2, 6.3, 12.5 µm |  |

| Visiotactile comparator Rubert and Rugotest E129-2: Shot-blasted surfaces: 0.4, 0.8, 1.6, 3.2, 6.3, 12.5 µm | |

| Visiotactile comparator Rubert and Rugotest E129-3: Grit and shot-blasted surfaces: N6, N7, N8, N9, N10, N11, equivalent to 0.8, 1.6, 3.2, 6.3, 12.5, 25 µm | |

Do not hesitate to download the notice (PDF format) for this product: