...A, D, D0, 0, 00

Graduation 0-100 per 1 Shore - measuring range 10-90

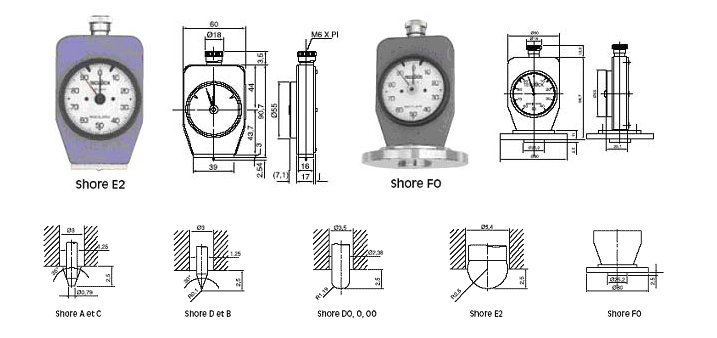

Shapes and dimensions of various indenters measuring range 2.5 mm Shore A and C Shore D and B Shore DO, O, OOShore E2Shore F

Reference : SOM-100

Shore D hardness tester

For hard rubbers, hard plastics, resins, etc.

In accordance with ISO 868DIN, 53505, ASTM D 2240

Penetrator: 30° cone Radius 0.1 mm

Without maximum indicator needle

Order number: SOM-300

Shore A hardness tester

For rubbers, elastomers, in general all soft products

In accordance with ISO 868, DIN 53505, ASTM D 2240

Penetrator: 35° truncated cone Ø 0.79 mm

With maximum indicator needle

Order number: SOM-400

Shore D hardness tester

For hard rubbers, hard plastics, resins etc...

In accordance with ISO 868DIN, 53505, ASTM D 2240

Penetrator: 30° Cone Radius 0.1 mm

With maximum indicator needle

Reference : SOM-400

Durometer Shore D0

For 1/2 hard rubbers, plastics

In accordance with ASTM D 2240

Penetrator: Half-sphere Ø 3.32 “Radius 1.19 mm

With maximum indicator needle

Order number: SOM-420

Shore 0 hardness tester

For soft materials

In accordance with ASTM D 2240

Penetrator: Half-sphere Ø 3.32 “Radius 1.19 mm

With maximum indicator needle

Reference : SOM-430

Shore 00 hardness tester

For foam rubbers

In accordance with ASTM D 2240

Penetrator: Half-sphere Ø 3.32 “Radius 1.19 mm

With maximum indicator needle

Reference : SOM-440

Shore F0 hardness tester

For very soft materials

OUT OF STANDARDS

Indenter: Flat Ø 25.2 mm

Base Ø 80 mm

With maximum indicator needle

Reference : SOM-200

Shore E2 hardness tester

For soft rubbers and gums

OUT OF STANDARDS

Penetrator: Half-sphere Ø 5 mm Radius 2.5 mm

With maximum indicator needle

Minimum thickness of sample to be measured: 6 mm If necessary, samples can be superimposed.

Use :

The part to be tested must be placed on a flat, rigid surface. Apply the indenter, avoiding the edge. Apply sufficient pressure so that the base of the durometer is in contact with the part. Wait about 15 seconds, then read the result. However, for instant reading, just wait 1 second. For greater precision, and if the shape of the part to be inspected allows it, it is preferable to use a fixture.

Shore A should preferably be used when values below 20 are obtained with Shore D. Similarly, use Shore D when values above 90 are obtained with Shore A.