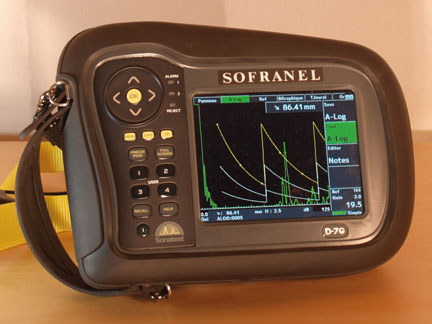

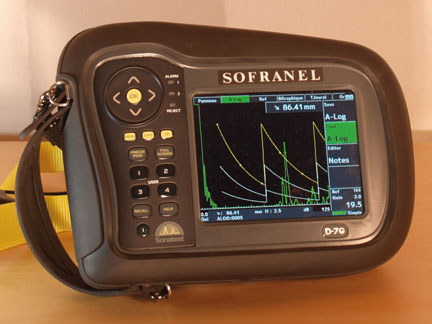

Sonatest has been designing ultrasonic devices for many years, with a focus on robustness and performance. The MASTERSCAN D-70 continues this tradition by providing you with these features. Its innovative hardware design allows you to add new functions through software updates without returning the equipment to the factory.

High resolution beneath the surface, excellent signal-to-noise ratio, and great sensitivity are key features of a device designed and assembled entirely in Europe.

The D-70 offers practical innovations to make your inspection work easier: measurement of the actual angle of your transducers, ease of evaluating transfer losses, and advanced thickness measurement functions. It provides all the tools and methods for sizing both common and specific defects. The D-70 is an essential and universal tool that will allow you to perform inspections in all kinds of industries and countries.

Typical applications include weld inspection, corrosion detection, inspection of forged and cast parts, aerospace inspection of metal or composite parts, nuclear sector inspections, and general ultrasonic testing.

Main Features

- Customizable and intuitive menus

- Split DAC/AVG/DGS

- Easy transfer loss evaluation

- Refracted angle measurement

- On-site configurable options

- On-site software update

- Encoded BScan

- Ascan with adjustable persistence

- 4 GB internal memory

- USB 2 interface for import/export to PC

- Video output for training

Reliable, Robust, and Sturdy

A design that allows work in harsh conditions and proven reliability are two key arguments for an owner of UT defect detection equipment. Maximum operability is ensured by a battery that provides up to 18 hours of autonomy on a full charge. The device casing is made from materials used in the automotive industry for their shock resistance. The IP 67 standard ensures the device's water resistance even in delicate conditions. The device's operation in explosive atmospheres is guaranteed by successfully passing MIL 810-G tests. Environmental tests have also confirmed that the device is fully functional up to external temperatures of 55°C. The MASTERSCAN D-70 and 700 M comply with the NF ISO EN 22232-1 standard.

High-Visibility Screen

For all defect detection devices, the screen is a critical point. The D-70 features a transflective color VGA screen that provides excellent visibility under any lighting conditions. Maximum readability is ensured by an adjustable brightness and a choice of 9 color palettes, including an LCD-like mode with black trace on a white background.

Simplicity reigns with an improved user interface and the ability to display the AScan in full-screen mode with just the push of a button. This configuration allows for detecting every detail on the trace.

The TFT screen does not suffer from the usual limitations of LCD screens, such as contrast variations with temperature or loss of contrast, which allows the D-70 to function in all weather conditions.

Filters

The Masterscan D-70 or 700M offers 8 different frequency ranges to optimize the signal-to-noise ratio for all your demanding inspections:

- 1) 100 kHz - 500 kHz

- 2) 200 kHz - 800 kHz

- 3) 0.4 MHz - 1.6 MHz

- 4) 1.4 MHz - 3 MHz

- 5) 3 MHz - 8 MHz

- 6) 7 MHz - 15 MHz

- 7) 9 MHz - 21 MHz

- 8) 1.6 MHz - 22 MHz (wideband)

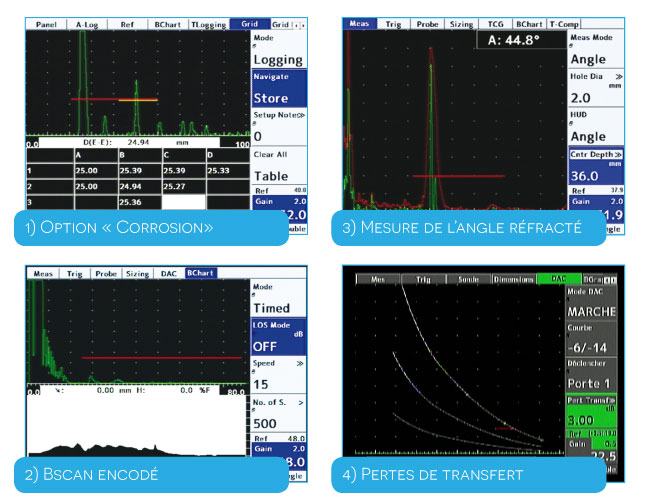

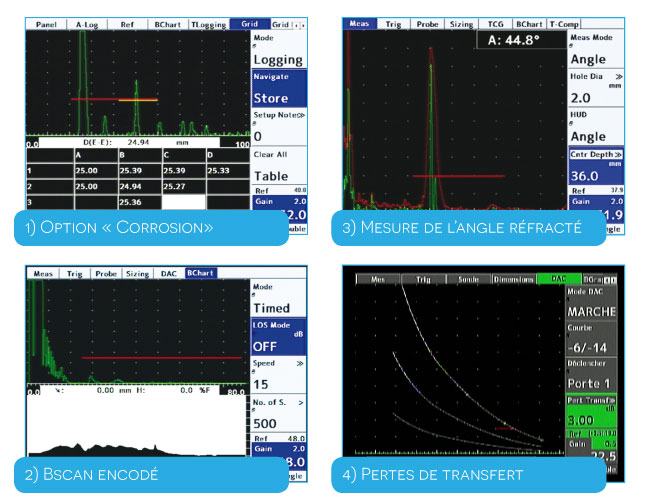

1) "Corrosion" Option: The "Corrosion" option gives access to two major functions in corrosion detection (2D TABLES documented).

The operator can easily create a 2D table by storing the A-Scan, B-Scan, thickness measurement (from previous or real-time inspection), and associated comments at each location.

2) Encoded BScan: The "Corrosion" software option allows the display of the BScan thickness profile for thickness measurements. This can be encoded with acquisition rates between 3 and 10 per second. The BScan can be stored and transferred to the PC for analysis on Utility. Most classic wheel or cable encoders can be used with the device. A specific menu allows the calibration of the encoder.

3) Refracted Angle Measurement: Rapid refracted angle measurement is now possible directly within the device. Simply enter the diameter of the test hole used and its depth, and the device will directly calculate the refracted angle in the part. This tool is very useful for checking transducers and during calibration.

4) Transfer Losses: The DAC curves as designed in the D-70 allow easy evaluation of transfer losses, even on welds of varying thicknesses. These can be added to the reference gain and stored for better traceability.

The D-70 guides you in correctly evaluating transfer losses through the structure of its menu.

The Masterscan includes sizing tools:

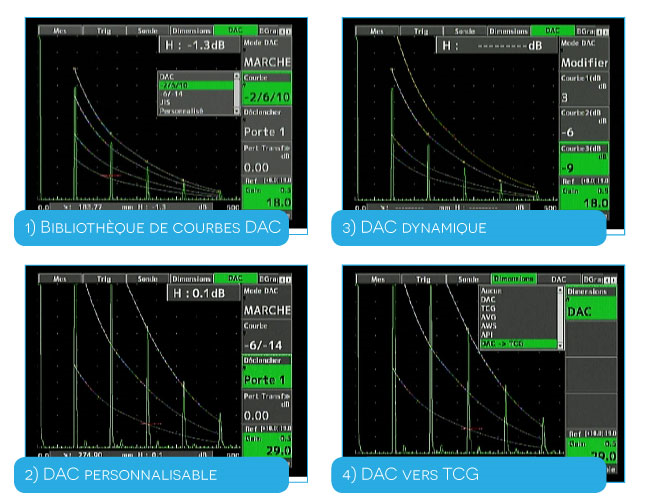

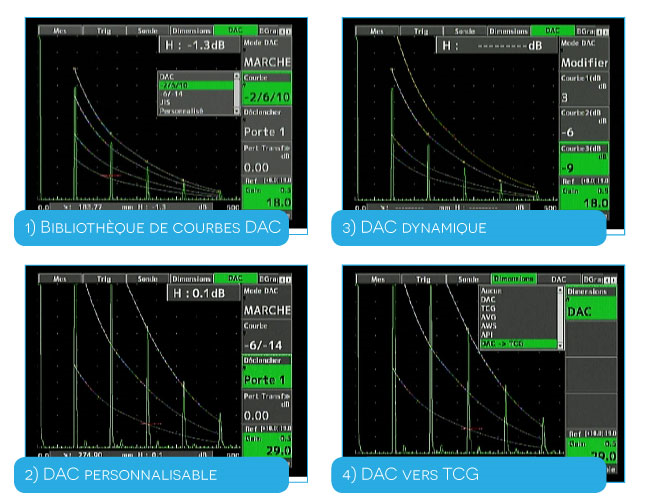

DAC

DAC curves can be built using up to 20 points and following the standards: JIS/ASME, EN 1714. The operator can choose whether the DAC curve or gate is used to trigger the alarm. Amplitudes can be displayed either in dB relative to the DAC, as a percentage relative to the DAC, or as a percentage of screen height.

1) DAC Curve Library:

The following pre-programmed standards can be used:

- EN 1714 (-6 dB; -14 dB)

- ASME (-2 dB; -6 dB; -10 dB)

- JIS DAC (+6 dB; -6 dB; -12 dB)

Any of these levels can be used to trigger the alarm. The selected level is displayed with a different color compared to the other curves.

2) Customizable DAC:

Up to 3 additional custom curves can be displayed in addition to the reference curve. The operator can define the level of these curves between +20 dB and -20 dB relative to the reference curve. This ensures that all standards are supported by the device.

3) Dynamic DAC:

DAC curves can be adjusted by modifying the reference gain. The curves are then moved on the screen, either vertically or horizontally by changing the distance range. The relationship between the DAC curve and reference indications is perfectly managed through the estimation of transfer losses between the reference block and the part to be tested. The logical structure of the D-70/700S menus assists in this task.

4) DAC to TCG:

A DAC curve can be easily converted to TCG and vice versa. The conversion uses the reference points collected and keeps the reference gain for the leftmost point on the screen. All reference echoes are brought to 80% of screen height.

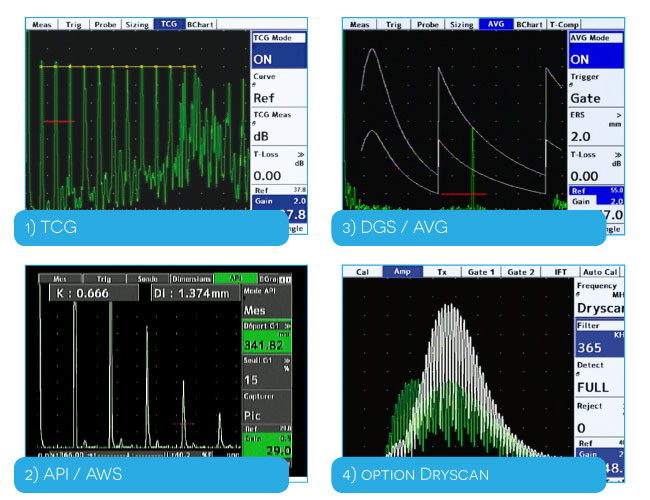

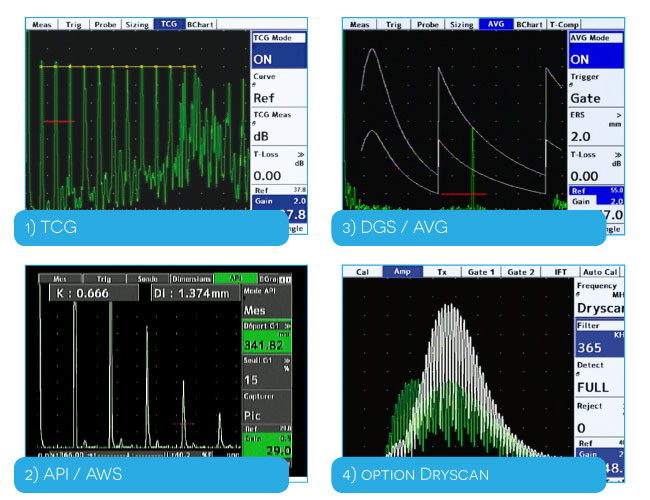

1) TCG: The TCG software option allows a variable gain based on time. It ensures that echoes corresponding to a standard defect size, such as a 3mm diameter hole, maintain a constant amplitude of 80%, regardless of depth. The D-70 with the TCG option allows switching between DAC curves and TCG curves and vice versa.

2) API: The API (American Petroleum Institute) option evaluates indications based on the API 5UE method. The R and D values are displayed on the screen.

3) DGS/AVG: The DGS/AVG software option can be configured for any transducer. It enables reliable and reproducible sizing in equivalent Flat Bottom Hole (FBH). The FBH response curve can be adjusted on screen to display the desired acceptance level and used to trigger alarm thresholds and measurements. If the "Split-DAC" option is also installed, the same functionality can be used for AVG curves.

4) AWS: The AWS (American Welding Society) option allows evaluation of indications based on the criteria used in AWS D1.1, namely indication level (IL), attenuation factor (AF), and indication rate (IR).

Accessories

Sitescan Standard Kit, includes:

D-70 or 700S device, battery, charger, AC power cable, user manual, certificate of conformity, carrying case, Utility Lite software, USB cable, 1 bottle of couplant.

Rubber Protection Case

A rubber protection case perfectly molded to the D-50 device is available as an option to protect the device from severe impacts. (D-70 only)

"Pelican" Transport Case

To protect your device during all transport and storage. Compartmentalized cases.

- D-VALISE for D-70

- S-VALISE for SS-700

Encoded BScan Transducer Holder

Sonatest devices are compatible with many encoded transducer holder systems. The EZScan holder above may be offered by Sonatest for performing encoded thickness profiles on pipelines, tanks, vessels, or flat plates with an outer diameter of over 100mm. This holder features an integrated encoder, magnetic wheels, and inlets for water supply to the transducer.

This transducer holder is designed for separate E/R transducers with a 10mm diameter.

"Welding" Kit

The "Welding" kit includes device, transducers, and basic accessories for standard weld inspection:

- 1 D-70 device

- 1 protective case

- 1 MAM45-4 transducer, 4 MHz, 45° 8x9

- 1 MAM60-4 transducer, 4 MHz, 60° 8x9

- 1 MAM70-4 transducer, 4 MHz, 70° 8x9

- 1 separate E/R transducer MDER-4; 4 MHz, 0°

- 1 V2 BEM2 wedge

- 1 IS319-21-A1 wedge, 25mm thickness

- 3 Lemo 1 / Lemo 00 cables

- 1 double Lemo 1 / Lemo 00 cable

- 1 liter of PMUC - UCA2 couplant

- 1 D-VALISE protection case

Utility Lite / Utility PRO (Data Management)

The Utility Lite software provides everything you need to manage your inspection data. The Lite version is supplied with each device and allows you to view, save, and manage your settings files, AScans, BScans, and thickness measurements both on your PC and on your device. With Utility Lite, you can also create predefined inspection report formats, copy-paste information into other applications, and create PDF documents.

- Load, store, and manage files on both PC and connected device

- Backup, analyze, define color coding for thickness grids, and export data to spreadsheets, databases, and data management software

- Update your device by searching for the latest version on the Sonatest website

Utility PRO is the professional version and is particularly effective with the "CORROSION" option. This version allows the user to create and manage inspection plans, notes, measure histories, and other information required by CMMS software.

- Defines inspection plans, grids, notes, and comments

- Imports previous data into the inspection plan

- Exports acquired data from the inspection plan to spreadsheets and maintenance management databases