STANDARDS : ASTM D4541, ASTM D7234, AS/NZS 1580.408.5, BS 1881-207, DIN 1048-2, EN 12636, EN 13144, EN 1348, EN 1542, EN 24624,ISO 16276-1, ISO 4624, NF T30-606, NF T30-062

The F506 is a lightweight, portable and easy-to-use adhesion gauge, available in analog or digital versions. It measures the tensile adhesion of coatings and can be used on site or in the laboratory. It has a capacity of 50 Mpa (7250 psi).

Thanks to its design, the F506 applies a uniform force over the entire range; simply turn the crank gently to guarantee reproducible results and accuracy of ± 1%.

Allows easy attachment of 14.2 mm, 20 mm or 50 mm diameter studs. Used in conjunction with the range's many accessories, it enables adhesion testing of coatings on flat or curved, thin or thick substrates, including wood, cement or other fibrous materials.

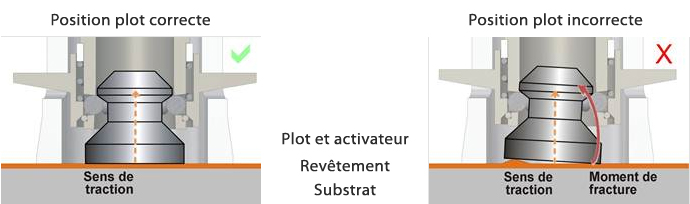

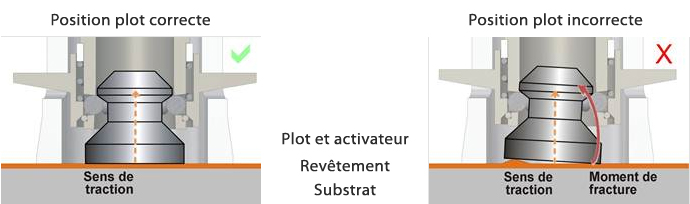

The F506 features a small, lightweight, ergonomic measuring head (activator), ideal for one-handed operation and adhesion testing in confined spaces.

Tests on vertical surfaces can also be carried out in complete safety.

Thanks to the magnetic clamp, the activator is held firmly in place to avoid any risk of accident in the vicinity of the test area.

Powerful

- Suitable for testing on metal, wood, concrete and other substrates

Strong & light - Ideal for regular checks

Steady rise in load up to 50 Mpa (7250 psi)

Versatile

- Portable, easy-to-use model

- Ideal for laboratory and on-site use

- Reusable 14.2, 20 and 50 mm (0.56, 0.76 & 1.96") diameter studs

- Measurement on small surfaces, curved or flat

Précis

- Measurement range up to 50 Mpa (7250 psi), accuracy ±1% of scale

Resistant

- Waterproof, powerful and shockproof

- Waterproof and dustproof, IP65 equivalent

- Suitable for harsh environments

- Testing coatings on low-cohesion substrates

When testing coatings on low-adhesion substrates such as concrete, wood or other fibrous materials, a larger stud is required to improve accuracy, repeatability and reproducibility.

The F506 tensile adhesion tester can be supplied as a kit or with individual 50 mm accessories (flange, stud, knife) to complement the F506 already in your possession.

|

Plot 14.2mm (0.56”) |

Plot 20mm (0.76”) |

Plot 50mm (1.96”) |

| Working range |

4 à 50 MPa (600 à 7200 psi) |

2 à 25 MPa (300 à 3600 psi) |

0.3 à 4 MPa (50 à 580 psi) |

| Scale resolution |

Analogique : 0.1 MPa (10 psi)

Digital: 0.01 MPa (1 psi) |

Analogique : 0.1 MPa (10 psi)

Digital: 0.01 MPa (1 psi) |

Analogique : 0.05 MPa (5 psi)

Digital:0.1 MPa (1 psi) |

| Instrument length |

290mm (11.5”) |

290mm (11.5”) |

290mm (11.5”) |

| Activator height (including collar) |

85mm (3.4”) |

85mm (3.4”) |

110mm (4.3”) |

| Instrument weight |

1.8kg (4lb) |

1.8kg (4lb) |

2.0kg (4.4lb) |

| Kit weight |

4kg (8.8lb) |

4kg (8.8lb) |

5.2kg (11.5lb) |

| Power supply |

2 x LR6 (AA) alkaline dry batteries (digital model only) Battery life: 2000 hours |

| Packing list |

| 20mm Kit |

F506 Adhesion Tester with 20 mm studs (x 10), standard flange for 20 mm studs, stud remover with handle, Araldite standard two-component epoxy adhesive (2 x 15 ml tubes), abrasive pad, carrying case, 2 x AA LR6 batteries (digital version only), test certificate and instructions. |

| 50mm Kit |

F506 Adhesion Tester with 50 mm studs (x 6), standard flange for 50 mm studs, shaft for 50 mm stud remover, 50 mm stud remover, Araldite standard two-component epoxy adhesive (2 x 15 ml tubes), abrasive pad, carrying case, 2 x AA LR6 batteries (digital version only), test certificate and instructions.Comment éviter les ruptures d'adhésion et de cohésion |

A) Prepare surface and stud

1. Choose a suitable test area, flat and wide enough to support the adhesion gauge.

2. Sand the pad and surface, and clean both to remove all dust and avoid any risk of adhesion failure.

B) Fixing the stud

3. Mix the adhesives correctly and apply a uniform film of adhesive to the entire surface of the pot.

4. Standards stipulate that the stud must be removed perpendicular to the test surface. The pad must therefore be fixed to a prepared, flat surface (see images below). Press down evenly on the pad to ensure that the face of the pad is parallel to the surface to be tested.

5. Remove excess glue from around the stud and allow to dry for as long as necessary. Adhesive tape may be required during the drying phase if the studs are applied to a vertical surface.

6. If necessary, once drying is complete, cut the coating around the stud using the cutter supplied.

7. Attach the gauge puller to the stud and begin testing.

C) Adhesion test evaluation

For the test to be valid, the coating must cover at least 50% of the stud face. If the bond has failed and there is no coating on the pad, or if it covers less than 50% of the pad face, the test is invalid and must be repeated.

If the layer has separated, and there is the same amount of coating on the pad and on the tested surface, this is called a “cohesive failure”.

Adhesive breaks” occur when the coating fails at the interface with another coating (leaving one coating on the pad and the other on the substrate), or when the coating has failed at the substrate (leaving the coating on the pad, and the substrate bare).

Note: if the adhesive rupture value is above specification, it can be noted in the report that the adhesion is above the specifications required for this test.