AEROSPACE

Specialized non-destructive testing solutions for the aerospace industry

We provide cutting-edge NDT services specifically designed for the aerospace industry.

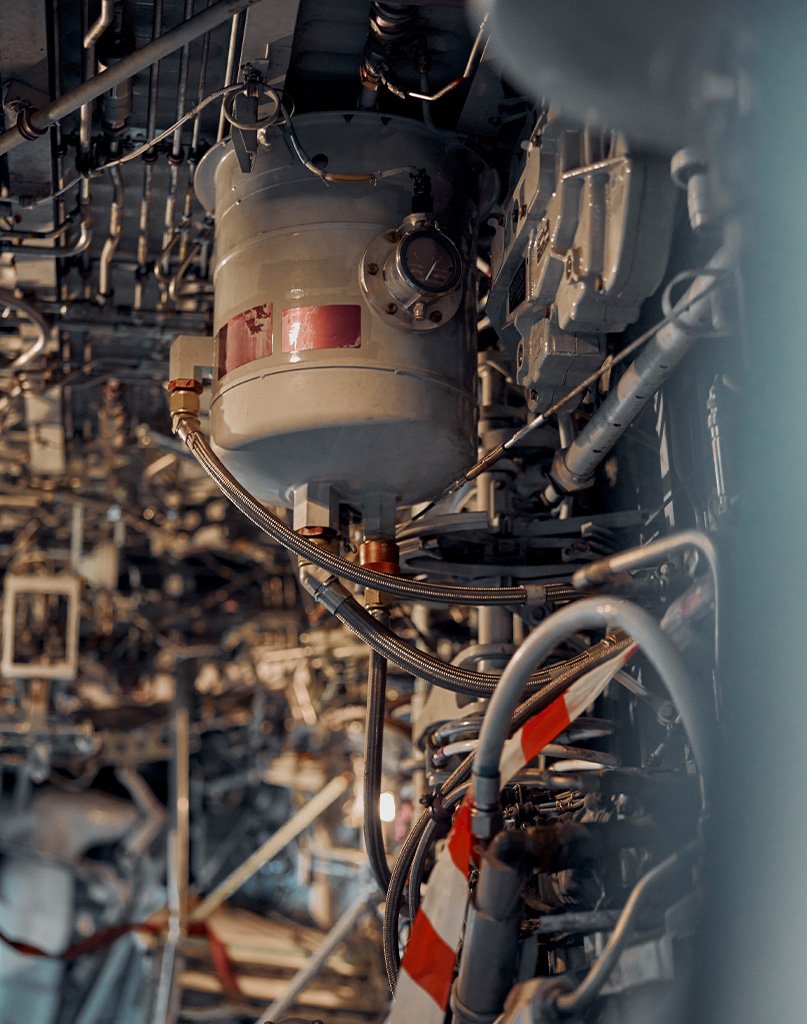

Sofranet offers top-tier NDT equipment, adapted to the stringent standards of the aerospace sector. Whether you maintain aircraft engines or inspect critical structural components, our solutions ensure the precision and reliability you need.

THE MOST USED TECHNIQUES IN AEROSPACE

Our Techniques

In the aerospace industry, precision and safety are non-negotiable. At Sofranet, we specialize in four essential NDT techniques that guarantee the integrity of aircraft components throughout their life cycle:

Common Aerospace NDT Applications:

Our NDT solutions are critical for ensuring the safety and performance of aerospace systems and components.

- Surface Crack Detection: Identifying surface cracks in components such as aircraft fuselage panels, wings, and engine casings to prevent fatigue and failure.

- Subsurface Defect Detection: Detecting internal defects in composite and metal materials, such as delamination, using advanced ultrasonic and radiographic methods.

- Conductivity Measurement: Measuring the conductivity of aluminum and other conductive materials to ensure material integrity, crucial for load-bearing parts.

- Material Integrity: Ensuring the overall integrity of structural components such as landing gear and engine blades, meeting the strictest safety and performance standards.

- Coating Thickness Measurement: Precisely measuring protective coatings on aerospace surfaces to ensure resistance to corrosion and environmental damage.

- Rivet Hole Inspection: Detecting cracks and fatigue around rivet holes in aircraft structures, particularly in areas of stress such as wings and fuselage.

- Wheel and Brake Inspection: Performing detailed inspections of aircraft wheels and braking systems to identify wear, cracks, and other potential points of failure.

- Bolt and Fastener Crack Detection: Ensuring the structural integrity of bolts, fasteners, and joints by detecting cracks at high-stress points, securing load-bearing areas.

- Composite Material Testing: Evaluating the quality and durability of composite materials used in modern aircraft construction, ensuring optimal performance under extreme conditions.

Get in touch with us

Have a question or just want to say hi?We’d love to hear from you.