Sofranel offers a wide range of non-destructive testing of materials, feel free to download our product catalog to find them.

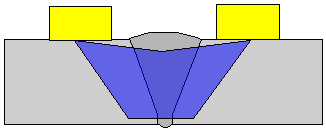

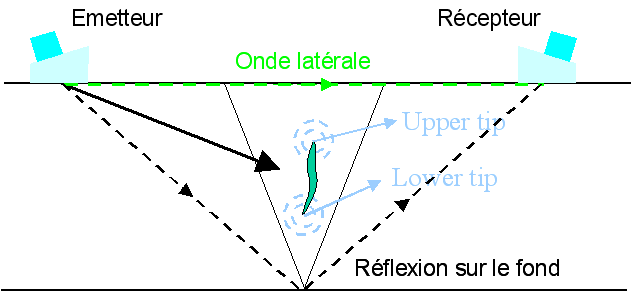

Control by TOFD method is to control a welding using two transducers positioned on either side of the weld, operating in transmission. Translators are selected such that the beam is highly divergent, and that "insonified" the greatest possible volume of the solder if not all of the weld. If a discontinuity is present in the solder, it will diffract a part of the energy according to the usual laws of acoustics. This is the diffracted energy that will be recovered by the receiving translator and which will be used to locate the discontinuity by measuring the flight time.

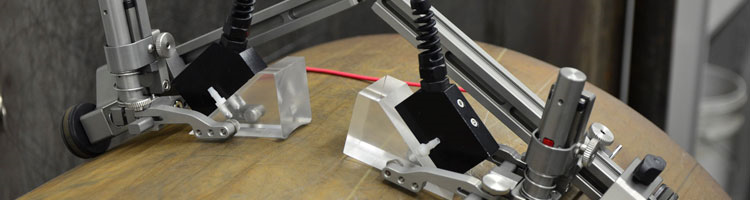

Truly robust device designed for construction use, portable, self-contained, which makes it easy to make acquisitions in the most difficult conditions.

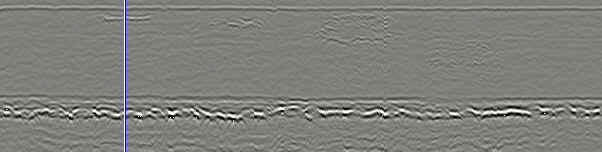

Objective: just make TOFD acquisitions and analyze them quickly. The TOFD images are encoded images for which a precise positioning of the position indication and the length is possible. TOFD calibration provides the depth of the indication and height. Hyperbolic faders to facilitate the design guidance. On the other hand, the information can be stored, and the operator can "replay" the acquisition sequence and confirm with the Scan the information present on the BScan image is consistent or not. Finally, the reporting tools allow you to quickly edit a report which may contain a defect table confirmed by the operator.

Some codes such as ASME 2235-9 have already validated the TOFD replacing radiography.

Contact us for more information and see the technological developments of ultrasonic testing.

Sofranel offers a wide range of non-destructive testing of materials, feel free to download our product catalog to find them.