Sofranel offers a wide range of non-destructive testing of materials, feel free to download our product catalog to find them.

The most common standard shims appear below. We can provide many other wedges on request with wedges flat bottom holes, drilled holes, specific dimensions of stepped wedges, stainless steel, aluminum ... Do not hesitate to contact us.

The teaching kits for Non-Destructive Testing is available for the following test methods: Ultrasound, X-ray, visual inspection, Magnetic / penetrant and Demonstration (multi-techniques).

These bags are a great support and training practice. They provide valuable information regarding: the different characteristic defects, how to identify them and interpret them according to the signals or information provided by these control processes. These bags also allow students to gain the experience necessary to compare the indications of defects identified on test specimens with macrographies and provided radiographs.

The use of these bags can reduce training time while greatly improving the understanding of driving faults, ultimately, a more reliable interpretation of information supplied by the different methods. They are designed to meet the growing needs of training and have been successfully integrated into many internationally recognized training programs, such as NCP, ASNT, DGZfP, Nortest, EN 473 and many others.

The terminology and fault descriptions are consistent with the AFNOR NF EN ISO 6520.1

These cases are available with specimens of carbon steel test, stainless steel or aluminum.

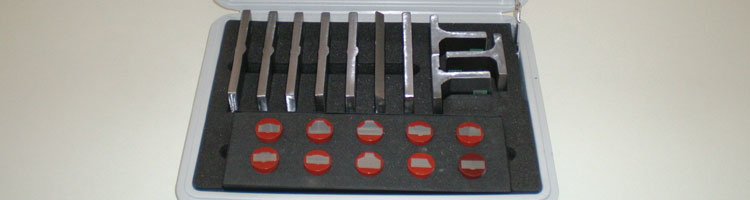

| A set of 10 test samples of easy handling, carbon steel, each having a different type of defect, size and specific location. All these tubes are coated with a clear lacquer to prevent corrosion. | A photo radiograph (as appropriate) for each type of defect. Suitcases for ultrasound, magnetic and bleeding, as well as the demonstration case, contain examples of photo-rays. Suitcases for radiography contain radiographs of each specimen tested. Note: These radiographs were taken from carbon steel test specimens. |

| A macrographic cutting each defect covered with a transparent adhesive film to prevent corrosion. Note: All macrographic cuts are carbon steel. | Information on the location of faults: type, approximate dimensions and defect location. |

| Control criteria and acceptance. | A magnifying glass. |

| A certificate of giving information on the test criteria used (to allow for comparisons). | These suitcases, attractive and robust, are made of light gray polypropylene with molded black compartments. Dimensions and weight: 42 x 37 x 12 cm, 11 kg |

The teaching kits on the magnetic and penetrant contain an identical choice of samples with defects leading surface. However, it is appropriate to allocate, distinctively, a suitcase for testing bleeding and another for magnetic testing. Indeed, the magnetic pigments of magnetic inks tend to partially obstruct or plug the open defects, so the penetrating penetrant used can not penetrate into the defects, which will make unreliable the penetrant testing. If it is still possible to make a reliable control Magnetic after penetrant testing, the converse is not true: hence the need to allocate a suitcase nondestructive test method.

3 T-shaped test pieces and the test pieces 7 in the form of platelets have a selection of defects leading surfaces such as those commonly encountered. They allow to understand and identify the types of defects and compared with macrographic cuts and photo-rays provided. Furthermore, detection of the basic techniques and interpretation of faults leading surface can be developed.

Material : Carbon steel.

The test piece T-shaped and the other 9 specimens in the form of platelets have a selection of welding defects and discontinuities commonly encountered. They allow to understand and recognize the types of defects and compared with macrographic cuts and photo-rays provided. In addition, fundamental techniques for the detection and interpretation can be developed.

Material : Carbon steel.

The test piece T-shaped and the other 9 samples in the form of platelets have a selection of surface defects or internal opening in the solder commonly encountered. They allow to understand and identify the types of defects based on ultrasound echoes and compare them with macrographic cuts and photo-rays provided. In addition, fundamental techniques of ultrasonic detection and evaluation of the defect size can be developed.

Material : Carbon steel or aluminum.

The test piece T-shaped and the other 9 samples in the form of platelets have a selection of defects leading surface and weld defects. They allow to understand and identify the types of defects and their radiographic images, and compare them with macrographic cuts and photo-rays provided. In addition, fundamental techniques of X-ray detection and interpretation can be developed.

Material : Carbon Steel or aluminum

The test piece T-shaped and the other 9 samples in the form of platelets are a variety of carefully selected parts of each of the other cases, so as to provide an overview of the defects and their detection by the implementation of various techniques for nondestructive testing. In addition, samples may be used to demonstrate the advantages and disadvantages of each technique NDT.

Material : Carbon steel.

NOTE : All radiographs are true photographic reproductions of radiographs.

Therefore, they are only representative of the defects contained in the specimens provided.

| Summary table of the various types of faults : | |||||||

|---|---|---|---|---|---|---|---|

| Défaut | |||||||

| 1 | Connection crack | MT | PT | DM | UT | ||

| 1A | Transverse crack | MT | PT | ||||

| 1B | Transverse crack | MT | PT | ||||

| 1C | Connection crack soudure en T | UT | |||||

| 2 | Fissure en racine | MT | PT | DM | UT | RT | |

| 3 | Fissure de bord | ||||||

| 4 | Fissure longitudinale | MT | PT | ||||

| 5 | Fissure axiale en milieu de cordon | UT | |||||

| 6 | Soufflure pleine soudure (nid de soufflures) | DM | UT | RT | |||

| 6A | Piqûre | MT | PT | VT | |||

| 7 | Inclusion de laitier | DM | UT | RT | |||

| 8 | Manque de fusion des bords | DM | UT | ||||

| 9 | Manque de fusion à la racine | MT | PT | RT | |||

| 10 | Retassure à la racine | VT | DM | RT | |||

| 11 | Manque de pénétration à la racine (V simple) | VT | UT | RT | |||

| 12 | Excès de pénétration | VT | RT | ||||

| 13 | Manque de pénétration à la racine (V double) | UT | |||||

| 14 | Dédoublure au raccordement | MT | PT | ||||

| 14A | Dédoublure dans la tôle | MT | PT | ||||

| 14B | Dédoublure dans la tôle | UT | |||||

| 15 | Pénétration irrégulière à la racine | VT | DM | RT | |||

| 16 | Projections (ou perles) | VT | RT | ||||

| 17 | Caniveau | VT | |||||

| 18 | Passe finale excessive | VT | DM | RT | |||

| 21 | Fissure sous-cutanée (passe finale supprimée) | MT | PT | DM | |||

| 22 | Passe finale concave | VT | |||||

| 23 | Chanfreins non appairés | VT | DM | ||||

Sofranel offers a wide range of non-destructive testing of materials, feel free to download our product catalog to find them.